Tlhaloso ea Meta: Lekola mekhoa e tsoetseng pele ea ho etsa ente bakeng sa hlobo ea lebone la koloi. Ithute ka khetho ea thepa, moralo o nepahetseng, le mekhoa e tsitsitseng ea ho etsa mabone a koloi.

Selelekela

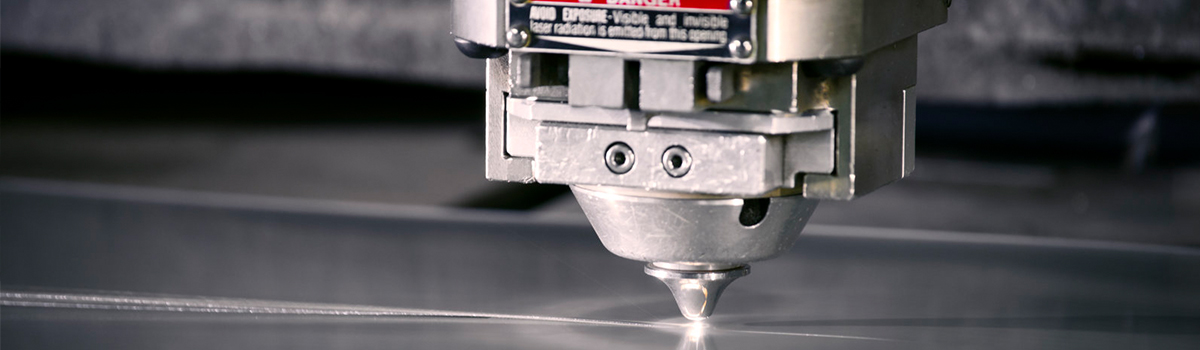

Indasteri ea mabone a likoloi e hloka ho nepahala ho feteletseng, ka hlobo ea mabone a hlooho e hlokang maemo a mamello tlasa 0.02mm. Ha meralo ea likoloi e ntse e tsoela pele ho ea ho li-ray tse nyane tsa LED le maballo a ho khanna a ikamahanyang le maemo, lienjineri tsa hlobo tsa ente li tobana le mathata a neng a e-so ka a bonoa. Tataiso ena e arola lits'ebetso tsa bohlokoa le maano a ho itlhopha a laolang tšimo.

1. Khetho ea Boitsebiso: Ho leka-lekanya Optics & Durability

Lintlha tsa bohlokoa tse reriloeng: mochini oa ente ea polycarbonate bakeng sa mabone a hlooho, thermoplastics ea boemo ba likoloi *

- PC (Polycarbonate): 90% ea mabone a morao-rao a sebelisa PC bakeng sa phetisetso ea eona ea 89% le mocheso oa 140 ° C.

- Lilense tsa PMMA: Lilense tsa bobeli hangata li kopanya PMMA bakeng sa khanyetso ea pele.

- Additives Taba: 0.3-0.5% UV stabilizers thibela mosehla; anti-fog agents fokotsa condensation ka hare.

Pro Tip: BASF's Lexan SLX le Covestro's Makrolon AL li fana ka phallo e ntlafalitsoeng bakeng sa liphaephe tse bobebe tse rarahaneng.

2. Moralo oa Core-Cavity: Ho sebetsana le Mathata a Thin-Wall

Lintlha tsa bohlokoa tse reriloeng: moralo o mosesaane oa lebone la lebone la lebota, liteishene tse pholileng tsa mabone a likoloi*

- Botenya ba Lerako: Mabota a 1.2-2.5mm a hloka ente ea lebelo le phahameng (800-1,200 mm / sec) ho thibela matšoao a ho tsilatsila.

- Pholiso e Tloaelehileng: Mecha ea alloy ea koporo e hatisitsoeng ka 3D e ntlafatsa katleho ea ho pholisa ka 40%, e fokotsa linako tsa potoloho.

- Surface Finishes: VDI 18-21 (textured) bakeng sa diffuser vs. SPI A1 (seipone) bakeng sa lilense tse hlakileng.

Thuto ea Mohlala: Tesla Model 3 matrix LED module e fihletse 0.005mm warpage e sebelisa taolo ea mocheso oa gradient.

3. Mekhahlelo ea Ts'ebetso: Ntlafatso ea Ts'ebetso ea Lintlha

Lintlha tsa bohlokoa tse reriloeng: liparamente tsa ente bakeng sa mabone a koloi, netefatso ea hlobo ea lebone la koloi *

| Paramethara | Mefuta e Tloaelehileng | Tšusumetso |

|———————|—————————————————————|

| Melt Temp | 280-320°C (PC) | Optical ho hlaka |

| Khatello ea Ente | 1,800-2,200 bar | E tlatsa likarolo tse nyane |

| Nako ea ho Paka | 8-12 metsotsoana | E thibela matšoao a sink |

IoT Integration: Li-sensor tsa khatello ea nako ea 'nete li fetola viscosity nakong ea ho tlatsa (Industry 4.0 e lumellana).

4. Mekhoa ea Moshoelella e fetolang indasteri bocha

Lintlha tsa bohlokoa tse reriloeng: liforomo tsa mabone a mabone a eco-friendly, lisebelisoa tse nchafalitsoeng maboneng a likoloi*

- Phetoho ea Lik'hemik'hale: Theknoloji ea ntlafatso ea PC ea Eastman e lumella 50% ea litaba tse nchafalitsoeng ntle le ho ba mosehla.

- Liaparo tsa Mold: Liaparo tsa PVD tsa CrN/AlCrN li lelefatsa bophelo ba hlobo ka 300%, li fokotsa litšila tsa tšepe.

- Poloko ea Matla: Likhatiso tsa motlakase ohle li fokotsa tšebeliso ea matla ka 60% vs litsamaiso tsa hydraulic.

Tlhokomeliso ea Taolo: Taelo ea EU 2025 ELV e laela 95% ho sebelisoa hape ha lebone la hlooho.

5. Emerging Technologies ho Shebella

Lintlha tsa bohlokoa tse reriloeng: AI ka moralo oa hlobo, liforomo tsa likoloi tse hatisitsoeng tsa 3D *

- AI Simulation: Autodesk Moldflow 2024 e bolela esale pele mela ea weld ka ho nepahala ha 92%.

- Hybrid Tooling: Lisebelisoa tse thata (HRC 54-56) tse kopantsoeng le 3D e hatisitsoeng ea conformal cooling.

- Smart Molds: Li-tag tsa RFID tse kentsoeng li latela nalane ea tlhokomelo le lipaterone tsa moaparo.

Qetello

Ho tseba ho bopa mabone a likoloi ho hloka ho kopanya mahlale a thepa, boenjiniere bo nepahetseng, le boqapi ba dijithale. Ha likoloi tse ikemetseng li khanna tlhokahalo ea lisebelisoa tsa mabone tse bohlale, ho sebelisa maano ana a tsoetseng pele ho tla beha baetsi ka pele indastering.

Pitso ea Ketso: U hloka tlhahlobo ea moldflow bakeng sa projeke ea hau e latelang ea lebone? [Ikopanye le litsebi tsa rona] bakeng sa therisano ea mahala ea tekheniki.

Nako ea poso: Apr-01-2025